1) Adopt the most advanced gloves production technology and production process layout, product qualification rate is more than 98%, protein content is lower than 120 micrograms per gram;

2) TPU Coating technology

3) Imported surfactant solidifier, finished membrane is uniform, no powder mold release

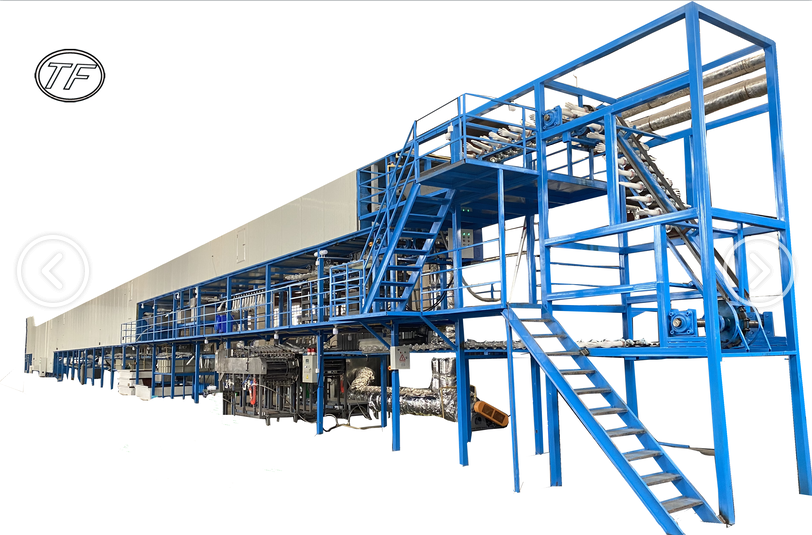

4) The introduction of foreign advanced transmission main chain structure, chain little resistance during operation, Production of high speed, stable operation

5) A main motor drag, solve the drag, difficult to synchronize, fault point, difficult maintenance, and other issues

6) Adopt vertical hot air circulation drying oven, compared with other forms of hot air circulation, save energy consumption by almost 20%

7) Used for cleaning mold splitter six roller long hair scrub mould technology;

8) Can design according to the needs of customers of different length, height, cost models;

Taifeng company, like the original mind, has always been committed to the production of professional, safe and reliable medical, inspection, household and industrial latex, nitrile glove production lines, mask machines, cigarette paper folding machines, cigarette paper printing and cutting machines, face napkins, napkins, toilet paper machines, balloon production lines and printing presses and other mechanical products., the company pays close attention to product quality and reputation, and has passed ISO9000 certification system and CE certification, so that the quality of the company's products is in line with international standards. The development over the years has been trusted and praised by customers, and the products are not only sold to most provinces and cities in China, but also exported to Spain, Egypt, Colombia, Japan, South Africa and other countries and regions.